- Home

- News

- Major project underway! SEMW supports the construction of China Shipbuilding’s Shanghai Research and Development Base!

Major project underway! SEMW supports the construction of China Shipbuilding’s Shanghai Research and Development Base!

SEMW Equipment, Win Another Battle

In Huangpu District, known as the “Window to Shanghai”

Shanggong is providing intelligent and digital construction solutions.

Helping Shanghai strengthen its research and development capabilities in shipbuilding and marine equipment

“Soaring” on a New Journey - Continue Watching

Major project underway! Shanggong Machinery supports the construction of China Shipbuilding’s Shanghai Research and Development Base!

Major project underway! Shanggong Machinery supports the construction of China Shipbuilding’s Shanghai Research and Development Base!

Shanggong Machinery has taken note.

Today, let’s step into…

Shanghai Major Construction Projects Plan for 2025

China Shipbuilding Group Shanghai Research Base Construction Project

Look at the MS series twin-wheel mixing drill from SEMW

How to overcome construction challenges and facilitate the construction of “major projects”

(Construction contractor: Shanghai Kaiben Foundation Engineering Co., Ltd.)

(Construction unit: Yixing Jinyiqiang Construction Engineering Co., Ltd.)

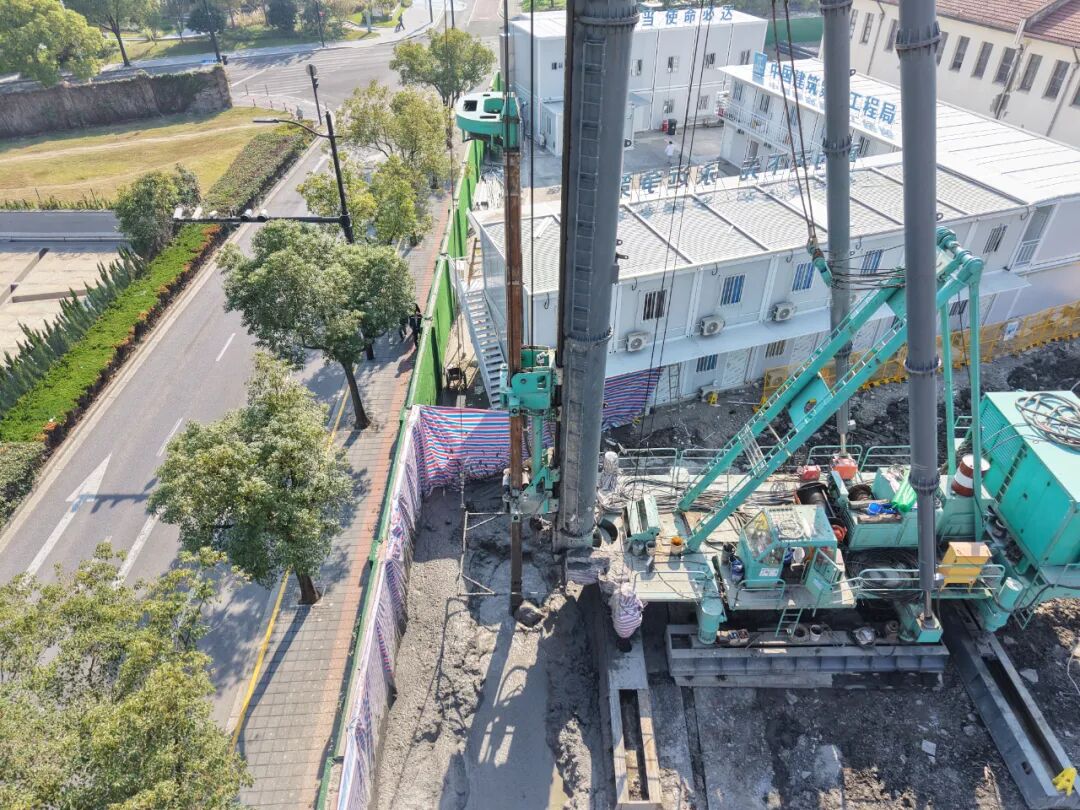

The China State Shipbuilding Corporation (CSSC) Shanghai Research and Development Base is located in Wuliqiao Subdistrict, Huangpu District. With a total investment of approximately 4 billion yuan and a total construction area of 180,000 square meters, it includes headquarters office buildings, a research and development center, and supporting facilities. The project focuses on the research and development of shipbuilding and marine engineering equipment and is a core component of Shanghai’s efforts to build a world-class shipbuilding industry cluster.

01

Major projects, significant implications

As part of Shanghai’s major construction project plan for 2025

This project aims to enhance the research and development capabilities of ships and marine engineering equipment.

Promoting the transformation of the traditional shipbuilding industry towards digitalization and greening

Support technological breakthroughs in cutting-edge fields such as intelligent ships and deep-sea equipment.

Serving the national maritime strategy is of great significance.

The successful construction of the underground cement-soil mixing water-stop wall in the early stage of the project

This marks a crucial step forward in the project’s construction!

02

High difficulty, guaranteed to win

The total volume of the underground water-stop curtain in this project is 22,000 cubic meters.

Depth 44m, wall thickness 800mm, cement ash content 25%

The project is located in a complex environment, near the Huangpu River.

Involving sensitive protected objects such as historical buildings and underground pipelines

The geology consists of silty soil from the riverbank, which is prone to collapse and seepage.

Extremely high precision is required for water stopping.

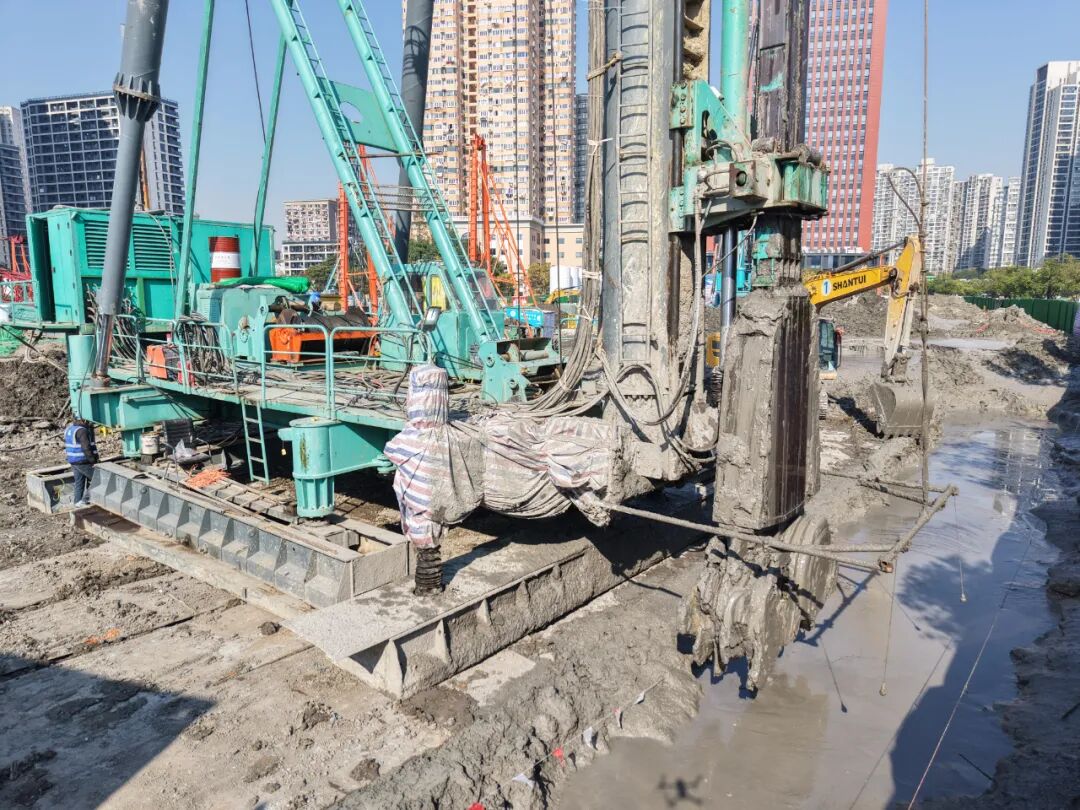

SEMW series dual-wheel mixers are supported by intelligent construction software.

And excellent product quality and stable equipment performance

With a construction efficiency of 3 walls in 15 hours

The on-site water-stop curtain project is progressing smoothly.

Drilling down, lifting, and mixing—the movements are all done in one smooth motion!

03

Intelligentization demonstrates strength

The intelligent control system of the SEMW series dual-wheel agitator

Preset milling head, hydraulic drill, air compressor,

Control parameters such as the inclination angle of the mixing head and other construction parameters are monitored.

Verticality and mud flow rate can be collected and monitored.

Data storage is also performed to ensure the quality of the wall construction.

The traditional hydraulic transmission system is replaced by a variable frequency speed control motor direct drive.

40% lower than that of traditional dual-wheel mixing drive systems.

It greatly reduces operating costs.

From drilling down to lifting, from mixing to building a wall

Every step has been meticulously calculated.

This showcases SEMW’s expertise in the field of green and environmentally friendly equipment manufacturing.

Leading strength

Supporting infrastructure construction

Moving towards higher standards and higher quality

SEMW, never stopping